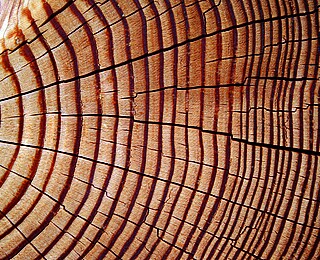

The renewable raw material wood: Less impact on the environment and healthier living

Sustainability has a long tradition at Hanse Haus. We decided to use wood as a building material back in 1929, when our company was founded as a small carpentry business called Hanse-Fertighaus-Bau in Lübeck-Travemünde.

We have always built our houses using the so-called timber panel construction method. In the spirit of sustainability, only local timber is used for the construction of Hanse houses. This saves long transport routes and partially offsets the carbon footprint.

What makes Hanse Haus and our prefabricated houses special?

How much wood for a Hanse Haus?

Wood as a building material for your own four walls is considered to be one of the most environmentally friendly raw materials of all. Around 30 cubic metres of spruce wood are used for an average single-family house – an amount that grows back in German forests in just 23 seconds.

So in the time it takes you to read the last few lines, the wood required for a single-family house has already been regrown.

Responsibility when building a house

At Hanse Haus, we keep our supply chains as local as possible and ensure the high quality standard we require for our building materials. For example, we source the majority of our solid construction timber directly from a supplier in the Rhön region, just 30 kilometres from our company headquarters.

This enables us to achieve short transport routes and delivery times, which significantly reduce the emissions associated with the supply chain. We can rely on the trustworthy origin of the products and support the local economy at the same time.

Making sensible use of waste wood

Our aim is to minimise the amount of materials used in the production of our prefabricated houses and to achieve the highest possible recycling rate.

Wood accounts for more than half of the material used at Hanse Haus and is the only building material that can be completely recycled. Wood waste from our production is processed into wood pellets and chipboard or used to heat the factory buildings.

DGNB Gold as standard at Hanse Haus

Our tried-and-tested timber panel construction offers an ideal basis for sustainable house building.

In addition to their outstanding energy efficiency, our prefabricated houses fulfil the sustainability criteria of the German Sustainable Building Council (DGNB), meaning that we can guarantee that all houses with a Hanse Haus floor slab/basement from the almost finished completion level will be awarded the DGNB Gold certificate.

Why we rely on wood as a raw material for our prefabricated houses

Advantages of wood as a building material

Prefabricated houses made of wood are becoming increasingly popular as an alternative to brick-built houses – and for good reason: wood is a durable, environmentally friendly, sustainable, healthy, recyclable and thermally insulating building material with excellent properties.

Wood as a climate-friendly building material

Anyone who opts for a Hanse Haus prefabricated house in timber panel construction is building CO₂-neutral.

In terms of its eco-balance, wood is superior to other building materials throughout its entire life cycle - from extraction, processing and utilisation through to disposal. The renewable raw material wood is available regionally, acts as a carbon store during growth and utilisation and can be recycled or disposed of in a climate-neutral way.

Careful use of wood as a raw material

In Germany, wood is grown in sustainable forestry so that it will continue to be available in sufficient quantities in the future. In total, our forests grow by around 120 million cubic metres of wood per year, of which only around 76 million cubic metres are used annually. Through continuous reforestation, our forests can bind more and more CO₂: One tonne of spruce wood absorbs up to 1.85 tonnes of CO₂ from the air as it grows.

Over 90% of the wood we use for our prefabricated houses is already FSC/PEFC-certified and comes from local forests that are managed responsibly.

A healthy home for life

As a renewable, natural raw material, wood offers an ideal alternative to conventional building materials such as stone or concrete.

In terms of durability and resistance, wood can easily compete with other building materials. Prefabricated timber construction has developed significantly over the last few decades, so that prefabricated timber houses and solid houses have been considered to be of equal quality since the 1980s.

Since the health and well-being of the occupants has become increasingly important in house construction, wood can also score points as a particularly healthy building material that creates a pleasant indoor climate.

Energy-efficient living with wood

Wood as a raw material is already a material with excellent thermal insulation properties in itself and is in no way inferior to the energy efficiency of conventional building materials, even with thinner walls.

In combination with our all-round thermal insulation, the very high thermal insulation reduces the consumption of energy for heating, which at the same time conserves valuable resources and saves running costs.

We have been awarded the Blue Angel "low-emission" eco-label for the mineral wool insulation we use in our house construction. The mineral wool is produced with low levels of harmful substances and is harmless to health.

Recycling and climate-neutral disposal

From the wood residues that arise during timber extraction and processing to the demolition of a timber house – wood as a material is completely recyclable and is climate-neutral when it is disposed of.

We utilise the wood waste that is produced during the prefabrication of a Hanse Haus in various ways: Our trainees use the wood to make key rings as promotional gifts, some is processed into wood briquettes and chipboard and the rest is used to operate the heating systems in our factories.

Request without obligation & free of charge our prefabricated house catalog with detailed information about the company as well as all house designs or construction performance and equipment descriptions. In addition, you will find the prices for our campaign houses in our campaign brochure.